Emulsion Polymer Institute Annual Symposium

Technical Program

Lehigh University

May 31, 2019

Agenda at a Glance

7:45 Registration and Continental Breakfast

Session 1 Material Synthesis, Manufacturing and Characterization.

10:48 Direct investigation of microstructure dynamics during drying of colloid-polymer thin films, by Kaewpetch, Thitiporn, Graduate student, Chemical and Biomolecular Engineering, Lehigh University (Advisor: Professor James Gilchrist)

Session 2 Emulsions, Polymers, Colloids in Biological Systems.

Session 3 Advanced Applications of Emulsions, Colloids and Polymer Composite.

6:00 Speaker Banquet Reception, Lehigh University.

Full Program

7:45 Registration and Continental Breakfast

8:10 Opening of Symposium: The Important Interfacial Issues – EPI’s Vision and Approach at the Interface, By Professor Daniel Ouyang and Dr Lanfang Li, EPI, Lehigh University

This talk will cover EPI’s vision as the interface and liaison between Academia and Industry, between a diversity of disciplines within the Institute’s affiliated faculty members and industry partner members, and in the field of interfacial sciences. A few EPI research projects will be covered, which started from commercial interest, important from an industrial research point of view, yet benefited from a fundamental academic research approach.

Session 1 Material Synthesis, Manufacturing and Characterization8:48 Morphology Evolution in Seeded Emulsion Polymerization, by Shan Jiang, Ph.D., Assistant Professor, Department of Materials Science and Engineering, Iowa State University of Science and Technology, Ames, IA 50011, USA.

Emulsion polymerization is a versatile approach to produce different polymeric nanoparticle morphologies, which can be useful in a variety of applications. However, the detailed mechanism of the morphology formation is not entirely clear. We studied the kinetics of nanoparticle morphology evolution during a seeded emulsion polymerization using both experimental and computational tools. It was discovered that systematically adjusting the solvent will not only yield spherical seed particles of different size, but also dumbbell particles even without the second monomer polymerization. In addition to solvent composition, morphology can be controlled by crosslinking density and even simple dilution of the seed particles. The kinetics studies revealed an interesting transition from multilobe to dumbbell geometries during the secondary polymerization. Based on the results, a nucleation-growth model has been proposed to describe the morphology evolution and verification was offered by computer simulation. The key discovery is that nanoparticle morphology can be kinetically controlled by diffusion of the protrusions on the seed particles. The condition of seed synthesis and crosslinking density will drastically change the seed and final nanoparticle morphology.

9:24 Designed Hybridization – Acrylic-Epoxy Hybrid Dispersions for Industrial Coating Applications, by Andrew Hejl, PhD, Dow Coating Materials, The Dow Chemical Company, Collegeville, PA

The replacement of solventborne coatings with waterborne alternatives has been an ongoing challenge for decades. Many reactive thermosetting resins require the use of a solvent to manage viscosity yet still suffer from pot life concerns. Acrylic emulsion polymers are a waterborne alternative that have high molecular weight and good toughness but frequently require coalescent to aid in film formation.

Designed Hybridization technology can leverage the advantages of both systems by using a polymeric latex as a host to imbibe a reactive small molecule and form a waterborne hybrid dispersion useful in two-component coatings. In particular acrylic emulsion polymers have been used to host epoxy resins that can react to form thermosetting resins upon reaction with a curing agent. This approach can combine the benefits of using a thermoplastic latex (rapid drying, low viscosity, waterborne) with those of a thermoset polymer (crosslinking, chemical resistance). In order to properly develop an effective hybrid system many factors must be considered: small molecule solubility and transport, compatibility between the host and the reactive molecule and latex stabilization that does not interfere with the reactive chemistry. Acrylic-epoxy hybrid dispersions have been developed that address these issues. These new hybrid systems have been successfully used to replace conventional waterborne epoxy alternatives in concrete floor coatings and metal protection applications.

10:00 Coffee Break

10:12 The Ouzo effect as a means to perform efficient encapsulation, by François Ganachaud, Centre national de la recherche scientifique, France

The emulsification of any solutes (oil, solid, polymers, lipids…) by solvent shifting, also called the Ouzo effect, is a generic method to prepare, in a very simple and straightforward manner, submicronic droplets, nanocrystals, nanoparticles or nanocapsules, and liposomes, respectively. It consists in solubilizing the solute of interest in a fully water-miscible solvent (e.g. acetone, THF) and adding a large amount of water, possibly containing a surfactant or dispersant. Even if experimental data show similar trends and features among the different solutes, the physics of the process is not fully understood. There have been numerous reports on this issue these last 5 years that will be summarized and criticized in this talk, including some of our (in part unpublished) work. We will particularly focus on the thermodynamics and kinetics of the emulsification step and the reasons for colloidal metastability of the obtained colloids. I will finally summarize the resolved and open questions to be addressed in the future.

10:48 Direct investigation of microstructure dynamics during drying of colloid-polymer thin films, by Kaewpetch, Thitiporn, Graduate student, Chemical and Biomolecular Engineering, Lehigh University (Advisor: Professor James Gilchrist)

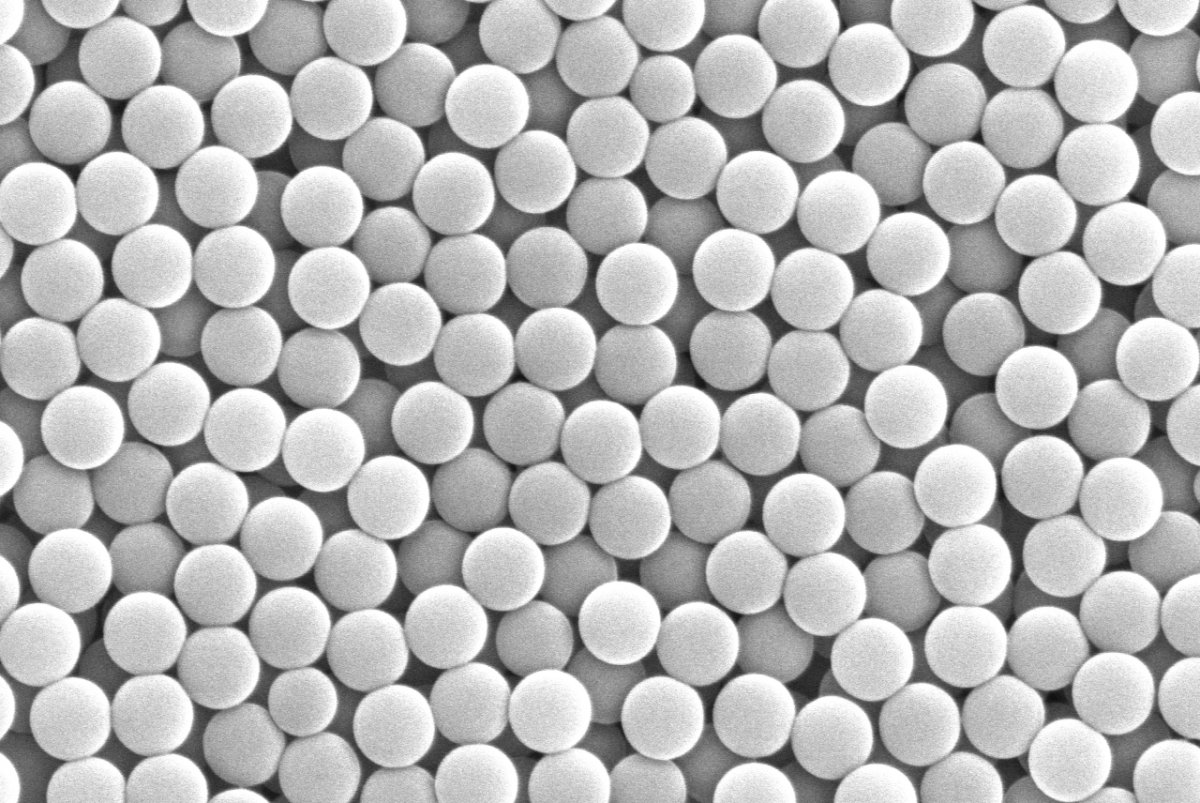

Drying process is essential to various industrial applications including pharmaceutical drug-release films for dermal and oral drug delivery. One of the primary concerns is the distribution of active ingredients within dry films. In colloid-polymer mixtures, the drying mechanism is complicated and its study is limited. Prior studies show the drying behavior of the colloid-polymer mixtures at various pH, including particle dispersion and flocculation due to depletion interactions between colloidal particles and non-adsorbing polymers by using small-angle X-ray scattering (Kim et al., Macromolecules, 49, 2016) and stress development (Kim et al., Langmuir, 25, 2009). Also, recent simulation suggests stratifications in drying colloid-polymer mixtures depending upon polymer chain length and colloid diameter (Michael et al., Langmuir, 33, 2017). This work is an experimental in-situ investigation of the drying mechanism and film formation of colloid-polymer mixtures using confocal laser scanning microscopy to visualize the internal structural evolution of surrogate “active” ingredients. The “active” ingredient is represented by fluorescent monosized 860 nm silica microspheres in a poly(ethylene oxide)-water solution. The mixtures prepared at high and low pH start as colloidal liquids or gels and are investigated over various colloid and polymer concentrations. Suspensions are drawn into thin films on glass substrates and dried at room temperature. During drying process, the film is evaluated by monitoring the dynamic evolution of the distribution and 3D structure of colloidal particles by analyzing the concentration profile, the number of nearest neighbors, the radial distribution function, and the Voronoi polyhedra distributions. In between these 3D scans, 2D scanning to determine the microrheology and internal flow is also obtained. The concentration and gel formation lead to the differences in particle distribution of the dry films. In gel samples, the time evolution of the structure is highly complex, sometimes experiencing periodic gel formation, gel breaking, flow and restructuring before the final structure is permanently immobilized. Moreover, the particle aggregation between liquid and gel mixtures during drying shows distinguishing patterns which are more comprehensible and useful for the industrial process and determining the final structure that dictates drug delivery.

11:00 Fingering Instability of Air Intrusion Into Drying Colloid-Polymer Films, by James Gilchrist, PhD, Professor of Chemical and Biomolecular Engineering, Lehigh University

We study experiments of drying colloid-polymer films similar to those used in many chemical and pharmaceutical applications. While flow and drying stresses set the colloidal microstructure of these films, after this microstructure is set we observe various modes of air entrainment into the matrix following various capillary, viscous, and elastic modes of instabilities. In this system, Haines jumps, capillary fingering, and crack formation at the bottom surface of this film follow their general understood physical phenomena. However, the predominant mode of air entrainment at moderate polymer concentrations shows micron-scale viscous fingering reminiscent of the Saffman-Taylor instability, yet at length scales much smaller than expected. In controlled drying in periodic systems using the ordered porosity in colloidal crystals, the viscous fingers are highly ordered and scale with the particle size and porosity. The onset and structure of this instability is characterized and a semi-elastic model driving the instability may be responsible for the short wavelength of the instability.

11:36 Monitoring drying process of droplets and latex systems using optical coherence tomography, by Yongyang Huang, PhD, Department of Electrical and Computer Engineering, Lehigh University

In this technical talk, I will report the recent progress of using optical coherence tomography (OCT) applications on non-destructive characterization of drying progression of droplets and latex systems. Employing time-lapse fast-scanning imaging, OCT can be used to monitor the dynamic process of drying colloidal droplets. With micron-size tracer particles which OCT can resolve individually, fluid flows have been captured; inward-moving phase boundaries are also visible in liquid crystal droplets. In a waterborne latex system, time-lapse M-mode or 3D OCT imaging shows spatial changes of micro-structures, i.e. detachment of latex, cracks and shear bands. With further speckle contrast analysis, 1D and 2D particles’ packing process that is initiated from latex/air interface can be monitored over time. OCT can serve as an experimental platform for fundamental studies of drying colloidal systems. It can be potentially employed as in-line quality control of polymer coatings and paints in industry.

12:12 Catered lunch

Session 2 Emulsions, Polymers, Colloids in Biological Systems

1:00 Organization of Associating or Crosslinked Actin Filaments in Confinement, by Dimitrios Vavylonis, PhD, Professor of Physics, Lehigh University

The filaments of the cellular cytoskeleton are able to organize in a variety of structures when polymerizing in confining spaces. In living cells, crosslinking interactions among actin filaments, together with geometrical cues and regulatory proteins can give rise to contractile rings in dividing cells and actin rings in neurons. Motivated by recent experiments that reconstituted contractile rings within small droplets, in this work we performed computer simulations to study basic aspects of the interplay between confinement and attractive interactions between actin filaments. We used a spring-bead model and Brownian dynamics to simulate semiflexible actin filaments that polymerize in a confining sphere with a rate proportional to the monomer concentration. We model crosslinking, or attraction through the depletion interaction, implicitly as an attractive short-range potential between filament beads. In confining geometries smaller than the persistence length of actin filaments, we show rings can form by curving of filaments of length comparable to, or longer than the confinement diameter. Rings form for optimal range of attractive interactions that exist in between open bundles, irregular loops, aggregated and unbunduled morphologies. The probability of ring formation is promoted by attraction to the confining sphere boundary and decreases for large radii and initial monomer concentrations, in agreement with prior experimental data. The model reproduces ring formation along the flat axis of oblate ellipsoids.

1:36 Dynamics of a single active particle in confinement, by Chong Shen, Grad student, Physics Department, Lehigh University (Advisor Prof Daniel Ou-yang)

Active colloidal systems contain active particles, which converts energy from the environment into directed or persistent motion. Due to the persistent motion, active particles behave differently to the conventional colloidal system. For example, active particles are likely to accumulate near the wall. Pure active particles have been intensively studied in the past few years, but the coupling between thermal and active motion is still not clear. Thus, we investigate from experiments and numerical simulation of single induced-charge electrophoresis driven metallic Janus particles in a quadratic potential. We found the maximum probability distribution in the histogram of position is away from the center, which can’t be described with Teff and Boltzmann distribution. The Kurtosis or shape of the histogram is controlled by rotational relaxation, the spring constant of trap and speed of the particle. Our experiments and numerical simulation provide how and when the non-Gaussian distribution appear, while interestingly, the coupling of thermal and non-thermal noise create a rich physical picture in a simple system.

1:48 Liquid-liquid phase separation of biomolecular condensates, by Steven MT Wei, PhD, Princeton University

There is currently a growing interest in understanding biopolymer liquid-liquid phase separation, particularly those involving intrinsically disordered proteins/regions (IDPs/IDRs). It has been determined that intracellular liquid-liquid phase separations underlie the assembly of many biomolecular condensates such as P granules, nucleoli, transcription factors, and stress granules. However, little is known about the physics of these organelles. In this talk, we discuss how molecular interactions and sequence-encoded conformational fluctuations of IDRs give rise to low overlap volume fractions for driving phase separations. Furthermore, we develop an optogenetic platform for light activation of IDR-mediated phase transitions in living cells. This powerful technique permits not only detailed studies of the mechanisms by which IDR sequences determine intracellular phase separation, but also synthetic biomaterials and cellular organelle engineering applications.

2:24 Coffee Break

Session 3 Advanced Applications of Emulsions, Colloids and Polymer Composite

2:48 Adhesion on Skin: A Challenge of Development of Long-Wear Cosmetic Products, by Hy Bui, PhD, Sr Principle Scientist, L’Oreal USA

In cosmetics, long-wear is a key attribute that consumers appreciate such as long lasting lipstick, long lasting foundation and mascara or UV gel nail polish.

To achieve a long-lasting effect, many cosmetic and personal care products utilize various film-forming agents. These film-forming materials are often adapted from industrial adhesives or coatings, because of their resilience in harsh environmental conditions. This makes them ideal to deliver long-lasting and non-transfer properties needed in cosmetic products such as lipstick and foundation.

However, adhesion on human skin is complex because the film- forming agents can be tacky on the skin, resulting in discomfort and consumer dissatisfaction. Therefore, balancing adhesion and comfort on the skin is imperative in developing a product, but it is also a technical challenge. Finally, these products often require specific removers due to their long-lasting properties.

This talk will focus on the challenges in the long wear of color cosmetics and review current polymeric film-forming systems that are used in cosmetic formulations to obtain optimal product performance.

3:24 Use of Colloidal Silica in Selective Laser Sintering of Polyamides, by Raymond A Pearson, PhD, Professor of Materials Science & Engineering, Lehigh University

Selective Laser Sintering (SLS) involves polymer powders that are about 50 microns in diameter. Such powders are heated to just below their melting point. A laser is used to selectively melt the SLS powders on a layer-by-layer basis. Powder flow is critical to the quality of the parts produced. Such parts are often weakest in the SLS build direction. The goal of this work is to use colloidal silica nanoparticles (~ 50 nm in diameter) to improve powder flow and to toughen interfaces in the build direction. Our latest results will be discussed.

4:00 Waterproofing and Water Resistance in Waterborne Coatings, by Wei Guo, PhD, Oriental Yuhong North American LLC, Spring House, PA

The coating industry in the Asia Pacific region trends towards low VOC, low odor, higher safety standards, healthy and 'green' coatings with more than 70% of coatings in the region are waterborne coatings. Water affects many water based paints and coatings. Long time exposure of water - a typical application scenario for waterproofing coatings - results in lower mechanical property, higher permeation, blister, delamination, adhesion failure, film degradation, and an early termination of service life. For waterproofing applications, waterborne coatings that are water resistant are highly desired. Water resistance of coatings is highly related to its water absorption rate. Factors such as hydrophobicity and crosslinking can reduce water absorption and improve the coatings water resistance. Here at the Oriental Yuhong North America, we develop water resistant coatings by thoroughly exploring the design space and balancing water resistance, other key properties, and cost.

4:36 Water Borne Coating in Cosmetic Applications, by Xianzhi (Joe) Zhou, PhD, Principle Scientist, Siliu Tan, Associate Principle Scientist, L’Oreal USA

A new era of sustainability is rising, and it’s touching every corner of the world. As consumers are increasingly motivated to be more environmentally conscious and are exercising their power and voice through the products they buy, waterborne technology has gained real momentum in the coatings industry. This talk will discuss potential application of water borne coating in cosmetics, especially in nail and hair styling field.

5:12 Concluding Remarks

6:00 Speaker Banquet Reception, Lehigh University

Speaker Biography (Alphabetical order)

Hy Bui, PhD, Sr Principle Scientist, L’Oreal USA

Dr. Hy Bui obtained BS degrees in Physics, Mathematics and Polymer Science at the University of Southern Mississippi (1995). Then, he worked as a associate chemist at Bayer in Coating Division. While at Bayer, he continued his education receiving a Master degree in Colloids, Polymers & Surfaces at Carnegie Mellon University (1997). He was awarded a Bayer Doctoral Fellowship and obtained his Ph.D. in Chemistry at Carnegie Mellon University (2004).

Dr Bui joined L’Oreal USA in 2004 as a Research Scientist in Make-Up Prelaunch team. For the last 15 years, he held many positions such as Head of Make-Up prelaunch, Head of Make-Up Applied Research, Scientific Director for Skin/Hair/Make-Up and currently is Sr. Principal Scientist and head of Physical Chemistry and Tranversal team in Applied Research. He contributed directly and indirectly to the launch of more than 45 cosmetic products to the market and obtained 104 granted US patents and 74 pre-granted patents. He was recognized as L’OREAL Expert in 2013 and L’OREAL Senior Expert in 2017. He also received the EPA US Presidential Green Chemistry Challenge Award in 2000 for two-component waterborne Polyurethane (withBayer).

François Ganachaud, PhD, Professor, CNRS (France)

Dr François Ganachaud is a chemist working for the CNRS in the field of polymers and dispersed media, for now 22 years. His interest on spontaneous emulsification was aroused in 2003 by a publication, published in Langmuir by Vitale and Katz, describing the generation of submicronic oil droplets by the so-called Ouzo effect. Since then, several fundamental and applied studies later, this process is almost fully mastered, and for sure applicable to the generation of a variety of colloidal nano-objects. Current studies are devoted to the generation of capsules and fluorescent tracers for biological applications.

James Gilchrist, PhD, Professor, Chemical and Biomolecular Engineering, Lehigh University

Dr. James Gilchrist is a Professor of Chemical and Biomolecular Engineering at Lehigh University. Gilchrist directs the Laboratory for Particle Mixing and Self-Organization with research interests spanning various particle technologies including nanoparticle self-assembly, suspension rheology and transport, coatings, microfluidics, chaotic mixing, and granular dynamics. He received his B.S. in Chemical Engineering from Washington University in St. Louis and Ph.D. from Northwestern University. Prior to joining the faculty of Lehigh University in 2004, he was a postdoctoral research associate in the Department of Materials Science and Engineering at University of Illinois working with Professor Jennifer A. Lewis (currently at Harvard University). He held Lehigh’s P.C. Rossin Assistant Professorship from 2007-2010 and the Class of 1961 Associate Professorship from 2013-2015, received the North American Mixing Forum Young Faculty Award in 2007, was a visiting professor in the Department of Chemical Engineering at the California Institute of Technology for the 2011-2012 academic year, and a Visiting Professorial Fellow at University of New South Wales in 2016. He is a member of EPI, the International Polymer Colloids Group, and the chair-elect of the AIChE Particle Technology Forum.

Wei Guo, PhD, Research Scientist, Oriental Yuhong North American LLC

Wei is a scientist at Oriental Yuhong North American LLC, Spring House, PA. He works on a number of research projects in waterborne coatings and waterproofing materials. Prior to Oriental Yuhong, Wei obtained PhD in Polymer Science and Engineering from the University of Southern Mississippi where he studied ultrathin polymer brushes and superhydrophobic surfaces. Before Southern Mississippi, Wei obtained BSs in Chemistry and Economics from Peking University.

Andrew Hejl, PhD, Sr Research Scientist, Dow Coating Materials

Andy Hejl is a Senior Research Scientist at the Dow Chemical Company. Since joining Rohm & Haas (later Dow Coating Materials) in 2007 he has developed waterborne coatings solutions across a range of applications including architectural, industrial, paper and leather coatings. His work includes research on latex blends to improve coalescent release recognized with Best Paper at the European Coatings Show and on Acrylic-Epoxy hybrid dispersions that was awarded Best Paper at the American Coatings Show. Andy has a PhD in Organometallic Chemistry from Caltech, obtained a B.S. in Chemistry from the University of Illinois Urbana-Champaign and was a Fulbright Scholar at the Technical University of Berlin.

Huang Yongyang, PhD, Electrical & Computer Engineering, Lehigh University

Yongyang Huang joined Lehigh University in 2013 and graduated in May 2019, as a PhD in department of electrical engineering (EE). His supervisor is Prof. Chao Zhou. Before Lehigh, Yongyang Huang got a bachelor’s degree in Physics from Peking University, Beijing, China. Yongyang’s research work focuses on the development of optical coherence tomography (OCT) technology, a 3D biomedical imaging modality with high resolution, imaging depth and speed. In the field of colloid science, Yongyang has explored the potential OCT applications in non-destructive characterization of various samples, including different droplet models and polystyrene latex system, in collaboration with Prof. Daniel Ou-Yang’s lab. Yongyang has been nominated as Rossin Doctoral Fellow of Lehigh University since 2016

Shan Jiang, Ph.D., Assistant Professor, Department of Materials Science and Engineering, Iowa State University of Science and Technology, Ames, IA 50011, USA.

Dr. Shan Jiang is an Assistant Professor in the Materials Science and Engineering department at Iowa State University. He obtained his Ph.D. from the University of Illinois at Urbana-Champaign, working with Professor Steve Granick on Janus particles. After graduation, he furthered his study at MIT Langer lab as a postdoc. He then worked at the Dow Chemical Company Coating Materials as a research scientist. He was the Dow Certified Green Belt Project Leader and worked on binder platform development for different products. Dr. Jiang has filed 3 U.S. patent applications and published more than 40 peer reviewed journal articles and book chapters. Dr. Jiang was awarded with the Racheff-Intel Award for Outstanding Graduate Research. The technology he participated in developing at Dow received the Presidential Green Chemistry Challenge Award and the R&D 100 Award. He recently received the ACS Younger Chemists Committee Leadership Development Award, the Education Leadership Award and the 3M non-tenured faculty award. His lab has received funding support from NSF, USDA, Center for Bioplastics and Biocomposites, Regents Innovation Fund and industry.

Lanfang Li, PhD, Associate Director, Emulsion Polymer Institute, Lehigh University

Lanfang Li is currently Associate Director and Chief Research Scientist at EPI, Lehigh University. Prior to EPI, Lanfang worked in the R&D functional role at Dow Chemical Company for 5 years, in corporate core R&D and Dow Coating Materials. She participated and lead multi-disciplineary research projects in optical, electric, and thermal functional coating materials, and authored 5 patents during this period. She obtained PhD in Materials Science from University of Illinois, Urbana-Champaign.

Raymond A. Pearson, PhD, Professor, Department of Materials Science & Engineering, Lehigh University

Raymond A. Pearson received a B.S. degree in chemistry from the University of New Hampshire and a Ph.D. degree in materials science and engineering from the University of Michigan. He joined the Materials Science and Engineering Department at Lehigh University, Bethlehem, PA in August of 1990. In 2010, Ray became a Fellow of the Society of Plastics Engineers and in 2018 he received the Award for Excellence in Adhesion Science from the Adhesion Society. Ray’s research interests include all aspects of processing, deformation, yield, and fracture of polymers with a focus on adhesion and interfacial issues. Notable research accomplishments include the elucidation of toughening mechanisms in rubber-modified and silica-filled epoxies. Recent efforts are focused on the mechanical behavior of nanoblends and nanocomposites as well as 3D printing materials (for FFF and SLS).

Siliu Tan, PhD, Associate Principle Scientist, L’Oreal USA

Dr. Tan is an associate principle scientist at L’Oréal USA since 2009 where she has made great contribution to a wide range of innovation programs in hair styling and hair care. Dr. Tan is Inventor/co-inventor on 30 US patents and 53 US patent applications. Prior to L’Oréal, she obtained PhD in Material Science Engineering from Stevens Institute of Technology focusing on coating Ag/Au nanoparticles using LBL coating in photonic crystal fiber for SERS detection.

Dimitrios Vavylonis, PhD, Professor, Department of Physics, Lehigh University

Dr. Vavylonis received a Physics BSc from the Univ. of Athens and a Physics PhD from Columbia Univ. in theoretical soft matter physics. He worked in biophysics as postdoc with Ben O’Shaughnessy and Tom Pollard before joining the faculty of the Physics Department at Lehigh University in 2006. At Lehigh he received the Libsch Early Career Research Award and was promoted to the rank of Professor in 2016. His group focuses on mathematical and computational modeling of the cellular cytoskeleton and related areas of cell biophysics. He had visiting positions at Univ. of Lausanne, AMOLF (Amsterdam) and Kyoto Univ. He is an editorial board member of Biophysical Journal, Cytoskeleton, Scientific Reports, and his work has been supported by NIH and HFSP.

Steven MT Wei, PhD, Princeton University

Ming-Tzo (Steven) Wei is currently a Postdoctoral Research Associate in the Department of Chemical and Biological Engineering of Princeton University. He received his Ph.D. in Bioengineering from Lehigh University in 2014. His research interests and work include Biophysics, Soft Matter, Polymer Physics, and Synthetic Biology. Most recently his research has focused on the synthetic nuclear bodies, the phase separation of disordered biopolymer, bio-rheology in nonequilibrium and nonlinear biopolymer system, colloidal electrokinetics, and the development of new microscopy.

XianZhi(Joe) Zhou, Principle Scientist, L’Oreal USA

Dr. Zhou received his Bachelor degree in polymer chemistry from University of Science and Technology of China and PhD in Polymer Chemistry from the University of California, Irvine. Prior to L’Oréal USA he was employed by Ciba Specialty Chemical company (Part of the BASF group now) as a synthetic chemist for home and personal care application. He joined Loreal USA in 2009 where he has made great contribution to a wide range of innovation programs in makeup and hair. Dr. Zhou is Inventor/co-inventor on 19 US patents and 45 US patent applications. In 2019 he is selected as L’Oreal Expert in the field of polymer chemistry.

Jiang, Joseph

Grad Student, advisor: Professor Daniel Ouyang, Lehigh University

Chong Shen

Grad student, Advisor Prof Daniel Ou-yang, Lehigh University

Kaewpetch, Thitiporn

Graduate student, Advisor: Professor James Gilchrist, Lehigh University